Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

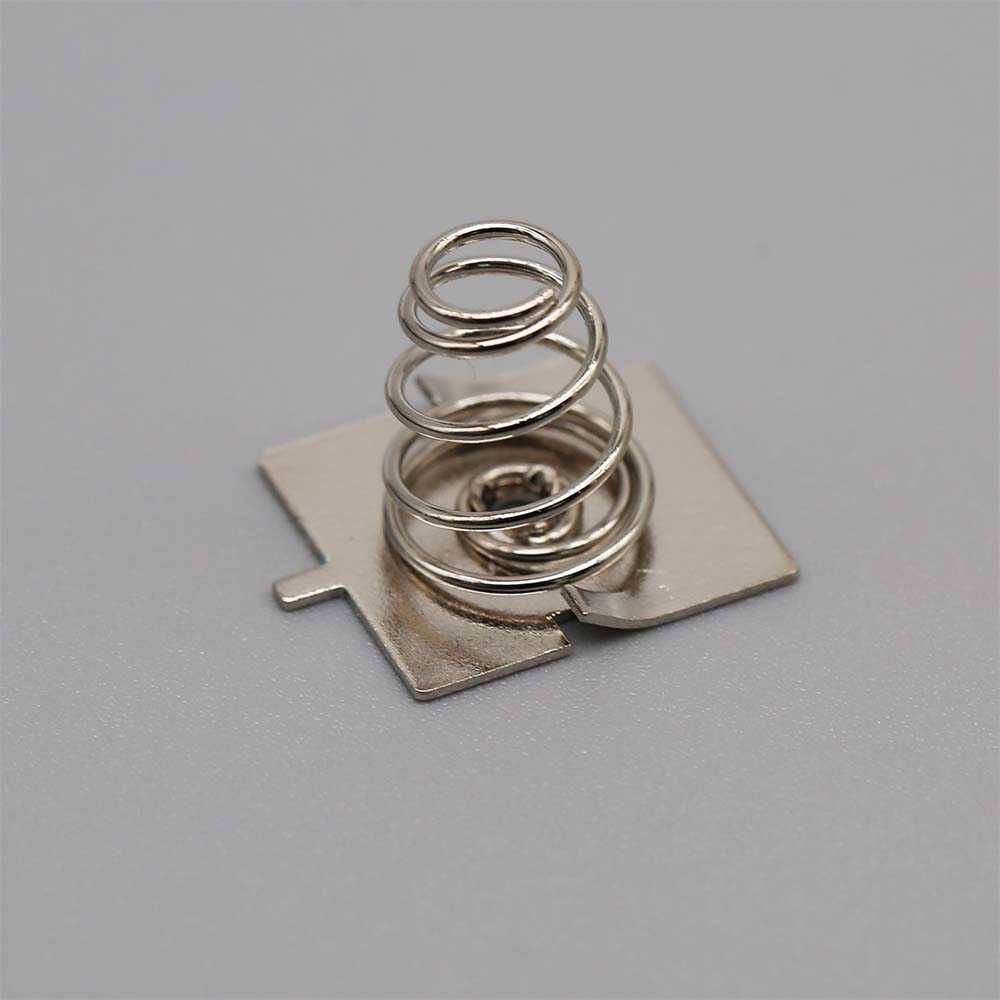

The metal shrapnel is generally made of metal shrapnel steel, which is used to control the movement of the machine parts, alleviate the impact or vibration, store energy, measure the size of the force, etc. It is widely used in machines and instruments. The types of metal shrapnel are complex and diverse. There are mainly spiral metal shrapnel, scroll metal shrapnel, plate metal shrapnel, etc.

The spiral metal shrapnel is a twisted metal shrapnel, and the working part is also tightly wound into a spiral shape. The end structure of the torsion metal shrapnel is processed into various shapes of torsion arms, not shackles. Torsion springs are often used in balancing mechanisms in machinery, and are widely used in industrial production such as automobiles, machine tools, and electrical appliances.

The application of gold shrapnel is more and more extensive, it can deform with the weight of the load, so what is the main function of the metal shrapnel? Let's take a look at it together.

The main functions of hardware shrapnel:

1. Used as a force measuring element, such as a force measuring device, a metal shrapnel in a metal shrapnel scale, etc. The ratio of the load to the deformation of the metal shrapnel is called the stiffness of the metal shrapnel. The greater the stiffness, the harder the metal shrapnel.

2. Control the movement of machinery, such as valve hardware shrapnel in internal combustion engines, control hardware shrapnel in clutches, etc.

3. Store and output energy as power, such as watch hardware shrapnel, hardware shrapnel in firearms, etc.

4. Absorb vibration and impact energy, such as buffer metal shrapnel under automobiles and train carriages, vibration-absorbing metal shrapnel in couplings, etc.

The material of the metal shrapnel:

The materials of hardware shrapnel include manganese steel, brass, stainless steel, phosphor bronze, etc. The specific choice depends on the use environment and other factors. For example, for general hardware shrapnel, as long as nickel-plated cold plates are used, the effect is good. The cost is not high. The embroidery resistance of brass shrapnel is obviously better than that of other materials in a humid environment, but the cost is higher. Of course, there are other factors, such as whether to weld or not, what the resistance is, etc. These must be considered.

Metal shrapnel is a metal stamping part, which is a mechanical spring part that uses elasticity to work. In the category of electronic hardware materials, it is made of stainless steel or manganese material after heat treatment. It is an important part of the switch. With the help of metal shrapnel The continuity of the product plays the role of a high-quality switch between the operator and the product. At the same time, using the stable rebound force of the dome (automatic return after pressing), and long life, provide the operator with high-quality tactile feedback.

Reasons for heat treatment of metal shrapnel:

1. Storage and output power can be used for other movements, such as in clocks.

2. Control mechanical actions, such as burning control valve, clutch hardware shrapnel.

3. Absorb vibration and impact energy, such as buffer springs, coupling damping springs under the car compartment.

4. As a strength element, such as the strength of the measured metal shrapnel.

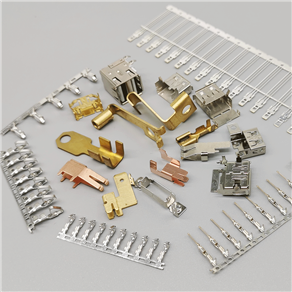

Advantages of BOSI Metal Shrapnel

1. Light weight, good stiffness, high strength, high precision, and oxidation resistance

2. The size of the same module is uniform and has good interchangeability and surface quality

3. The life of the shrapnel is 10,000-100,000 times, and the number of times of plugging force is more than 10,000 times.

4. Orthogonality 0.05mmMax, verticality 0.05mmMax, straightness 10mm, benchmark 0.05mmMax

BOSI material selection suggestion: For general hardware shrapnel, nickel-plated cold plate is used, and electronic hardware material is made of stainless steel or manganese material after heat treatment. Brass, phosphor bronze, and beryllium copper can also be used (heat treatment is required).

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

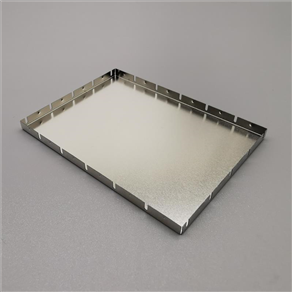

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

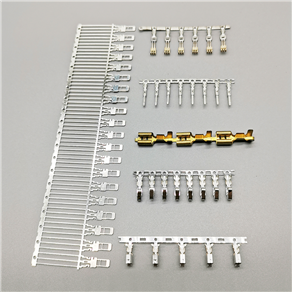

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

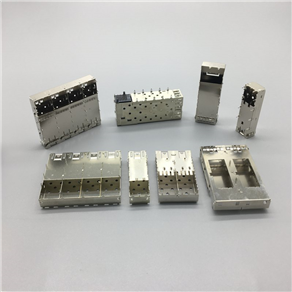

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子