Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

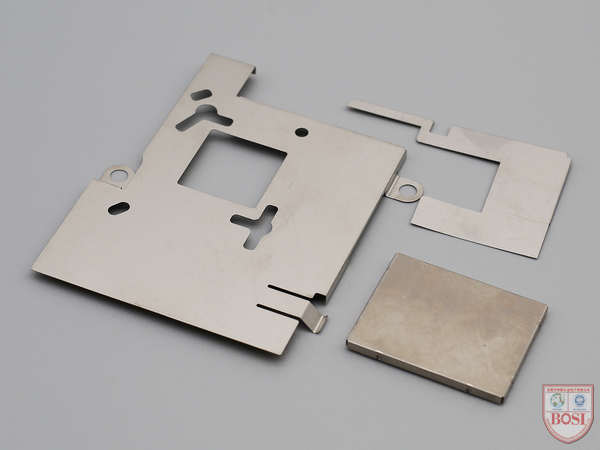

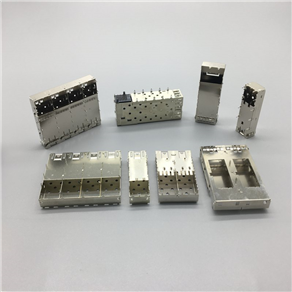

Copper-Nickel-Zinc Alloy shield cover is a tool used to shield electronic signals. After a period of use, the phenomenon of yellowing occurs. So what is the reason for the yellowing of the shielding cover? Let's interpret the reasons for the yellowing of the shielding cover and solve the problem of the yellowing of the shielding cover.

The reason for the yellowing of the Copper-Nickel-Zinc Alloy shield cover

1. After high temperature heating, the shield covers will turn yellow.

The Copper-Nickel-Zinc Alloy shield cover workpiece needs to be heated at high temperature during the processing (the white copper without high temperature resistant materials), and it will turn yellow when heated at high temperature. And another kind of white copper containing high temperature resistant material will not turn yellow after high temperature heating due to the particularity of the material composition. But the price is also relatively expensive.

2. Surface oxidation causes the shield covers to turn yellow.

The Copper-Nickel-Zinc Alloy shield cover inherits some of the chemical properties of the zinc element. If it is exposed to the air for a long time, the surface will be oxidized by the air and the color will turn yellow. Although yellowing will affect the beauty of the appearance, it has no effect on the performance of the product itself. Some people question the material and craftsmanship of the product because of the discoloration phenomenon.

In fact, the yellowing phenomenon is a problem with all ordinary white copper products, which has nothing to do with the material and processing technology, and this phenomenon cannot be changed by manpower. Don't worry, the performance of the white copper shield will change.

The solution for cleaning the yellowing of Copper-Nickel-Zinc Alloy shield cover

After seeking, we tried to use water-based cleaning agent to solve this problem, according to customer requirements without changing its existing production equipment and production process (cleaning process: ultrasonic cleaning → ultrasonic cleaning → pure water rinsing → pure water rinsing → Under the premise of pure water rinsing→pure water rinsing→pure water rinsing→drying), the foreign white copper degreasing cleaning agent MS66401N is customized.

The surfactant adopts a unique compounding technology, which has good emulsification, separation and penetration effects on the oil stain on the surface of the product, and due to the addition of copper protective agent, the defective rate of the product is effectively controlled during the cleaning process (the defective rate is in 3% or less), and in the later high-temperature welding process, the yellow glue is not prone to foaming, which greatly reduces the product defect rate and operating costs, and improves production efficiency.

The above is the reason for the yellowing of the foreign white copper shield: http://www.bosiwj.com/mp-02.html

If you are interested in purchasing a shielding cover, you can contact us Dongguan Bos Hardware. The flatness of our production process can reach 0.02mm and the accuracy can reach 0.01mm. Welcome to consult and quote.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

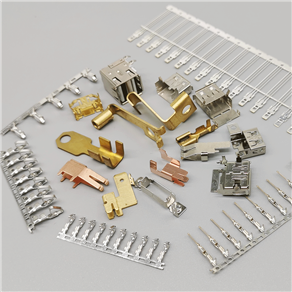

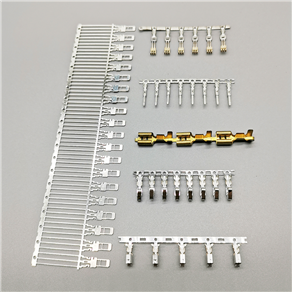

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

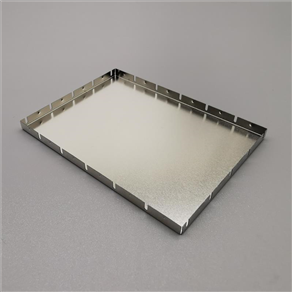

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子