Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

With the development of science and technology in the hardware and electronics industry, people's requirements for the precision of products are getting higher and higher. So how are precision stamping parts processed? Bosi takes everyone to find out.

First of all, for the precision metal stamping parts, we need to purchase the surface edge line of the stamping parts, and separate the stamping parts from the blank along the edge line. With a specific shape, such a complete precision stamping part is completed. Of course, stamping technology can also make its products into oval, annular and other shapes, which can be protected by spraying anti-rust paint on the surface. Increase its corrosion resistance.

For more than 20+ years, Bosi Hardware has been focusing on custom-made precision stamping parts, 20,000+ sets of die custom production, monthly processing capacity of 100+ sets of stamping dies, daily production capacity of 3 million stamping parts, stamping accuracy up to 0.01mm, 16 quality inspection layers Strictly check the layers, it is a benchmark enterprise in the metal stamping industry!

In the stamping processing industry, people's demand for precision stamping parts is also expanding. Precision stamping parts are not only high precision, but also have advantages that ordinary stamping products do not have in terms of appearance and durability. The production process of precision stamping parts is more complicated than that of ordinary stamping parts. Not only the shape and size of the product, but also stamping dies, punches, etc. must be considered during production. In order to ensure the production of qualified precision stamping parts, the following points should be paid attention to in the production process:

1. It is necessary to regularly check the performance of the punch press and the parallelism and perpendicularity of the slider and the table.

2. Strict installation requirements for the production of precision stamping dies. If the stamping factory does not have the ability to develop molds, it must find a more formal and powerful mold factory. The quality of precision stamping dies determines the quality of precision stamping parts. Money can't find a formal and incompetent mold factory. Dongguan Bosi's stamping mold development capability is ahead of its peers. There are a group of professional and technical personnel who have been in the industry for more than 20 years. They are skilled and the first choice for buyers!

3. Before installing the mold, be sure to strictly check whether the mold and the punch table are clean, and check the lubrication of the mold guide posts.

4. In the production process, the springs should be regularly checked and replaced to avoid problems with the springs that affect the quality of precision stamping parts.

5. When stamping workers install stamping dies, they must strictly install the rules and regulations to operate.

6. In the actual production process, if the mold blade is worn, it must be repaired or replaced in time, otherwise the damage to the mold will continue to increase.

To ensure the product quality of precision stamping parts, in addition to the same precautions as conventional stamping parts, the main thing is to pay attention to the precision maintenance and maintenance of punching machines and stamping dies. As long as the precision of punching machines and dies are guaranteed, plus regular operation can be produced. Produce qualified precision stamping parts.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

The importance of precision metal shields to shield EMI

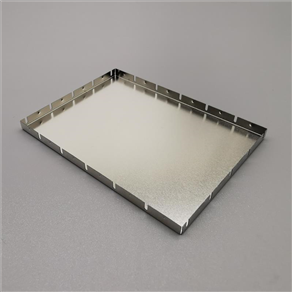

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

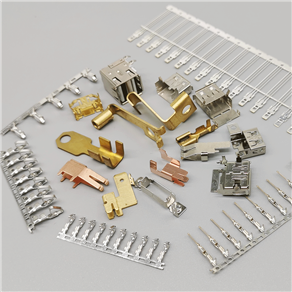

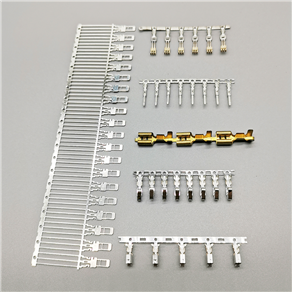

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

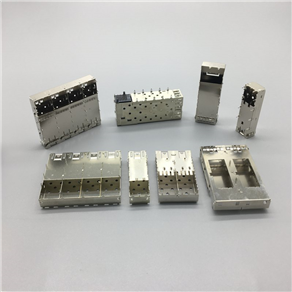

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子