Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

Definition of EMI:

EMI can be defined as electromagnetic wave energy that affects the function of electronic equipment. The source of EMI can sometimes be a naturally occurring environmental event, such as electrical storms and solar radiation; but more often than not, the source of EMI is another electronic device or electrical system. While EMI can be generated from any electronic device, some devices and components, such as cell phones, welders, motors, and LED screens, are more prone to interference than others.

Since electronics rarely operate independently, products are often designed to operate in the presence of a certain amount of EMI, which is especially important in military-grade and avionics and equipment that requires high reliability in all situations.

Briefly describe the importance of shielding cover to shield EMI.

1. The commercial necessity of shielding:

A project should consider shielding at the planning stage, so that the cost of shielding measures will be minimized. If you wait until the problem is exposed, then you need to pay a considerable price. Shielding measures often bring cost and increase in instrument weight. If it can be solved by other EMC methods, shielding should be minimized. (The implication is that shielding is the last resort)

2. The following two points should be noted for the PCB:

1> Make the wires and components as close as possible to a large metal plate (this metal plate does not refer to the shielding body)

2> Make electrical components and lines as close to the ground as possible (reduce the electromagnetic interference of interlayer signals, and the ground can absorb part of the interference). In this way, even if shielding is required, the demand for SE shielding effectiveness can be reduced.

3. The concept of shielding:

The shield is equivalent to a filter, which is placed on the propagation path of electromagnetic waves and forms a high impedance for a part of the frequency band. The larger the impedance ratio, the better the shielding effectiveness.

For general metals, a thickness of 0.5mm can produce a good shielding effect on electromagnetic waves of 1MHz, and can have a very good shielding effect on 100MHz. The problem is that thin-layer metal shielding is less than 1MHz or for pores, the shielding effect is not good. , this paper focuses on this aspect.

4. Large spacing and rectangular shielding will be better

(1) Larger spacing between circuits and shields can reduce mutual interference;

(2) The rectangular (or irregular) shielding shape can avoid frequency resonance as much as possible; the square shell is often easy to cause resonance;

But in general, the circuit board is generally located in the shield, and its components, lines, etc. will change the expected resonant frequency point, so don't worry too much.

As the leader of the EMI shield processing and customization industry, Dongguan Bos Hardware has been focusing on 20 years of dedicated research on shielding technology, and has introduced German CNC micro-proofing machines. Expedited sample production within hours, repeatability up to 0.01mm, flatness up to 0.02mm, pioneering in the industry, and capable of solving the pain points and difficulties of customers customizing precision hardware non-standard parts, Booz EMI shielding cover has good shielding effect and high precision. The first choice for our customers to purchase!

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

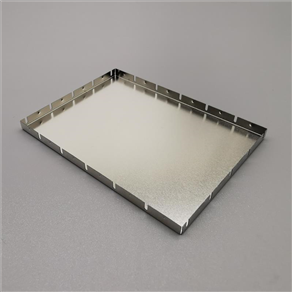

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

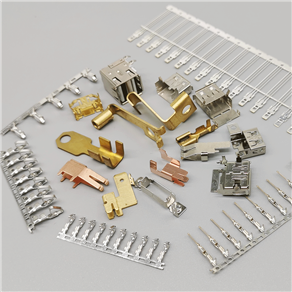

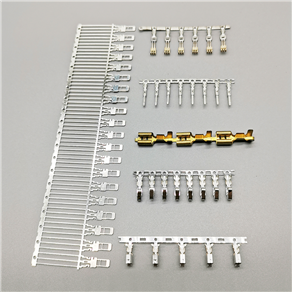

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

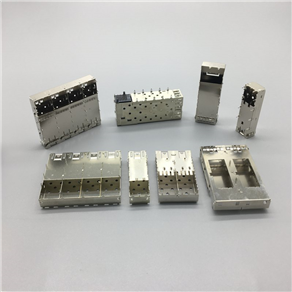

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子