Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

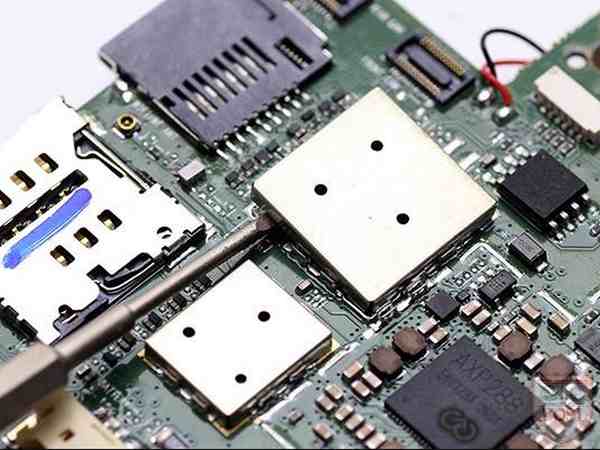

The mobile phone shield cover is mainly used to surround the interference sources of components, circuits, assemblies, cables or the entire system to prevent the interference of electromagnetic fields from spreading out. Generally, 0.2mm thick stainless steel and white copper are used as materials. In the process of production, there may be some exceptions. The following is a summary of several abnormal situations for your reference.

Five cases of abnormal quality of mobile phone shield cover:

1. The inner and outer surfaces of the product, and the inner and outer surfaces of the product are crushed: There are two cases:

(1) Small hole jumping waste, big hole jumping waste: long-term production causes the wear gap of the punch edge to become larger, and the waste cannot be stuck, and is brought out of the die surface by the punch, causing pressure injury.

(2) Chip crushing: The gap between the punch and the knife edge is too large or too small, resulting in powder chips falling on the die surface. When the material passes through the leveling machine and the feeder, the product will be directly crushed due to the dust and fine iron filings in the machine.

2. The burr of the small hole of the product and the burr of the fold of the shear belt:

The gap between the punch and the blade is too large to cause burrs or the punch is biased to one side, resulting in burrs on one side and no burrs on the other. The last step of our mobile phone shield is made with a shear belt and a folding structure. The punch is worn out after a period of production, which is prone to burrs.

In the last step, because the material is not pressed or the punch is bent to pull the material, the product produces peculiar smell, which causes one side to be cut more and the other side to be cut less, and the less side will protrude and cause poor size. In the last step, sometimes because the guide needle pulling material is knocked off, it will cause unstable bending and shearing dimensions.

3. There are few holes on the front side of the product:

No punching and shearing oil is added in production, the punch is broken; the small hole waste is blocked in the leakage hole due to too much oil, and the punch is broken; the foot shift blocks the leakage hole; the suction funnel blocks the leakage material The hole will break the punch.

4. The bending angle of the outer and inner buckle:

When the mold is stretched out, the die is not crushed to death; there is a large amount of waste in the mold, the product; the gap between the bending punch and the insert becomes larger; the wear or collapse of the pressure rib of the bending insert will cause the angle to expand. Inner buckle, the mold pressure is too dead; the bending insert pressure is too high; the gap between the bending punch and the insert is too small, which will cause the angle to buckle.

5. Side scratches:

The bending punch or the bending insert is worn; the gap between the bending punch and the insert is too small; the bending punch and the insert are stuck with waste; less oil will cause scratches.

The above is about the abnormal situation of the mobile phone shield: http://www.bosiwj.com/mp-03.html

Let you know where the problem is and avoid abnormal situations during production. If you are interested in shielding covers, bosi recommends a professional shielding cover manufacturer - Dongguan Bosi Hardware, we introduce German CNC proofing technology, three days proofing without mold opening, welcome to consult and quote.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

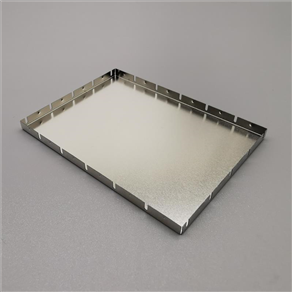

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

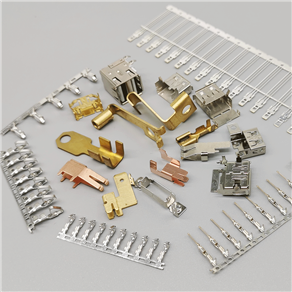

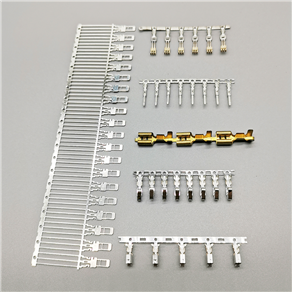

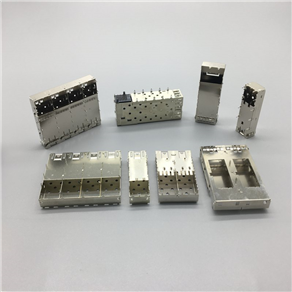

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子