Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

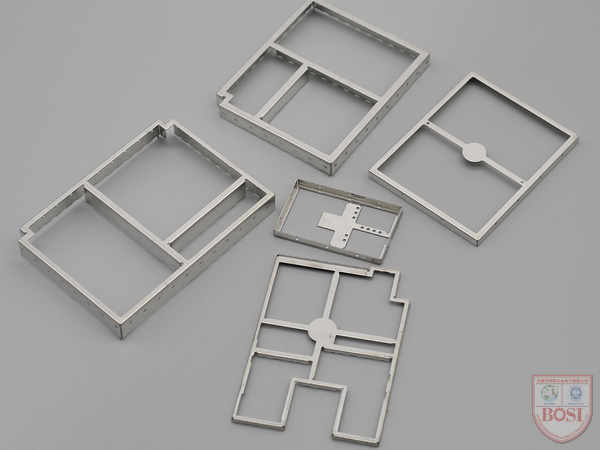

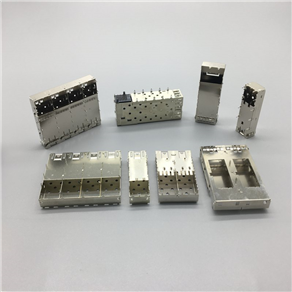

As mobile phones, computers, GPS, and other digital products become more and more popular, more and more are required, and more and more shielding covers are required. Then, what should shield covers manufacturers pay attention to when producing shielding covers , in order to ensure the production of high-quality products. The following editor will popularize the precautions for the production of shielding covers for everyone, and which technical requirements need to be paid attention to.

Precautions for the production of shield covers:

The shielding covers is generally made of stainless steel for bending, deep drawing, tin-plated steel strip, tinplate, etc. It is required that there is no oil pollution, no drape, no scratches, no deformation, the stamping tolerance is within 0.1MM, the size of the reclaiming point of the shielding covers should be appropriate, the reclaiming point should be in the middle of the material as much as possible, and the size of the reclaiming point should preferably be Φ6. 0mm, the larger the pick-up point, the higher the undisturbedness of the patch, and the higher the efficiency.

The flow space of the tray on which the shielding cover is placed is too large, and it is easy to swing during patching, resulting in failure to pick up. The material must be placed in the tray, and there is a flow space of about 1.0MM. If it is too large, it will cause the material to swing. If it is too small, the material may not be taken. come up.

Precautions when making shielding brackets

There should be one or two through holes with a diameter of 0.7~1mm on each side of the surrounding wall of the shielding bracket for the shielding cover. There should not be too many card holes, otherwise it will be difficult to disassemble, which can be made by the supplier, and we give the position size. The bottom surface of the surrounding wall of the shielding cover should be 0.5mm away from the PCB to prevent the shielding bracket from eating too much tin against the shielding cover. The diameter of the heat dissipation hole of the shielding cover is 1mm. If the shielding cover or the shielding bracket has a plane drop, pay attention to the side cut through the boundary of the drop, otherwise it cannot be processed.

In addition, a hole with a diameter of 3mm should be punched at the corner of the drop in the plane, otherwise it will be torn. If the shield cover or shield bracket has a plane drop, pay attention to the drop angle of 35~40 degrees. The shielding bracket has a plane drop, and the gap between the bracket and the cover surface at the drop is not 0, but should be 0.1mm.

The cutout part of the shielding bracket of the metal shielding cover should be more than 1mm away from the outer wall of the side wall. If there is a downward bend inside, the side wall at the bending place should be 0.5mm away from the outer wall. At this time, the plane is directly attached to the side wall and cut out. 15 Cut the shielding bracket The corner of the empty area is R0.5mm. The shielding bracket and the PCB are not welded on the whole surface. The Great Wall feet should be welded in a 2-1-2-1mm method. The metal shield can thus increase the attachment strength of the shield cover.

The above are the precautions for the production of shielding covers: http://www.bosiwj.com/mp-04.html

Our company's mobile phone shield cover are mainly made of 0.2MM white copper and stainless steel stamping, which can provide products with accurate dimensions, good flatness, easy tinning, good shielding performance, easy assembly, firmness, and excellent quality.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

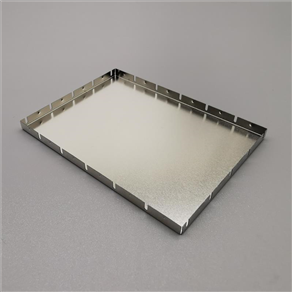

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

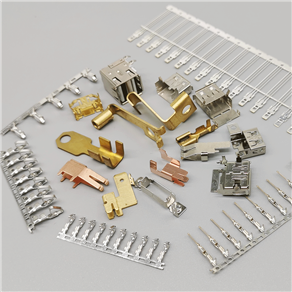

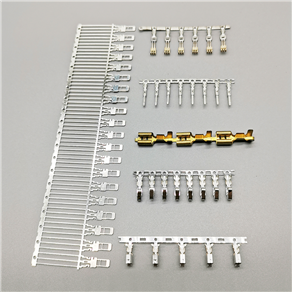

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子