Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

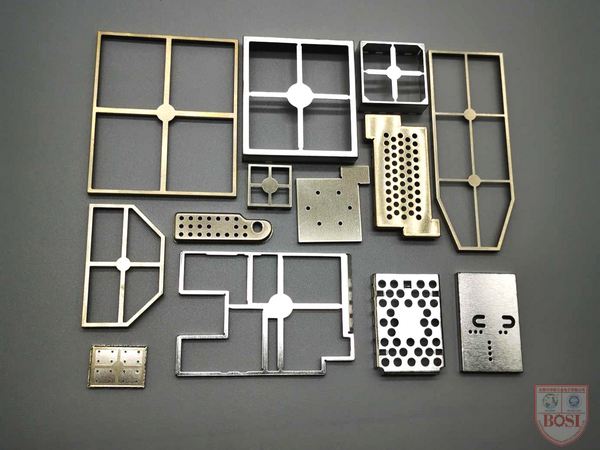

We Dongguan BOSI Hardware has more than 10 years of experience in the precision stamping industry, and we know almost the process flow of the precision metal stamping of the shield cover. It has high advantages and is widely used in various fields. Bosi will introduce the precautions for the stamping process of the shield cover.

What should be paid attention to in the stamping process of the shield cover?

1. The number of processes of the shield stamping part mainly depends on the complexity of its structure and shape, and it depends on the number of bending angles, relative positions and bending directions. When the bending radius of the bending part is less than the allowable value, a shaping process is added after bending.

2. The number of processes of shielding stamping parts is related to material properties, drawing height, number of drawing steps, drawing diameter, material thickness and other conditions, which can only be determined by drawing process calculation. When the fillet radius of the drawn part is small or the dimensional accuracy is required to be high, a shaping process needs to be added after the drawing.

3. The determination of the number of processes should also be in line with the company's existing molding capacity and the status of stamping equipment. The molding ability should be able to meet the requirements for the corresponding improvement of mold processing and assembly accuracy, otherwise only the number of processes can be increased.

4. When the cross-sectional quality and dimensional accuracy of the stamping parts of the shielding cover are high, it can be considered to add a trimming process after the blanking process or directly use the precision blanking process.

5. In order to improve the stability of the shield stamping process, it is sometimes necessary to increase the number of processes to ensure the quality of the shield stamping parts. For example, additional positioning process hole punching in the bending part, increased deformation relief hole punching in the forming process to transfer the deformation zone, etc.

6. The blanking of shielding cover stamping parts with simple shapes is completed by a single-process die. For blanking workpieces with complex shapes, due to the limited structure or strength of the mold, the inner and outer contours should be divided into several parts for blanking, and multiple stamping processes are required.

7. The use of special stamping oil can effectively improve the process accuracy, and fundamentally eliminate the problems of non-special oil products such as rapeseed oil, mechanical oil, and regenerated oil sticking to the machine and irritating the skin.

8. When working, you should always follow the safety regulations. For example, when stamping, you must always implement the prescribed safety systems; wear work clothes and work caps when working, work seriously, always stick to your post, and focus your thoughts to prevent personal accidents.

9. The first piece of shielding cover must be inspected and can be produced only after being qualified. During the stamping process, self-inspection and special inspection should be carried out at any time. When a fault occurs, the machine should be stopped immediately, and the relevant departments should be reported to the relevant departments in time.

The above are the precautions for the precision stamping process of the shield cover: http://www.bosiwj.com/mp-07.html

We have been producing shielding covers for more than 10 years at Dongguan Bosi Hardware. You can click [Metal Shielding Covers] to learn about our product information. If you want to know more about our products, you can contact us directly.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

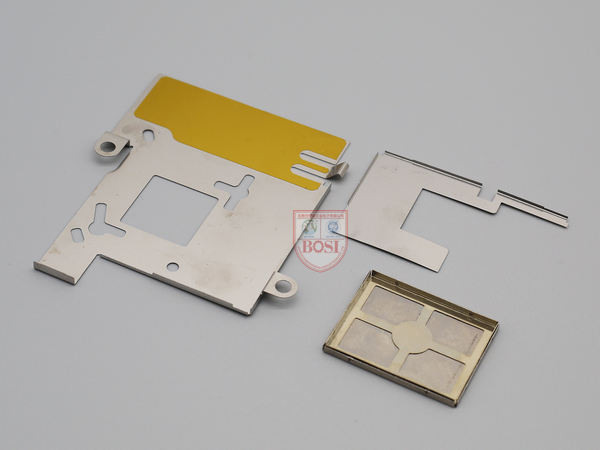

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

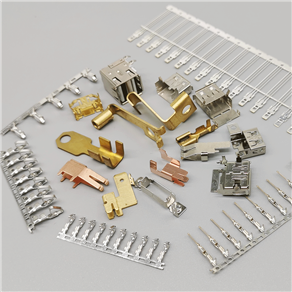

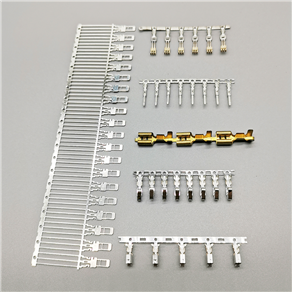

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

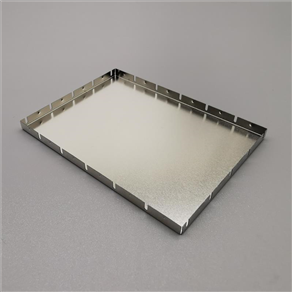

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

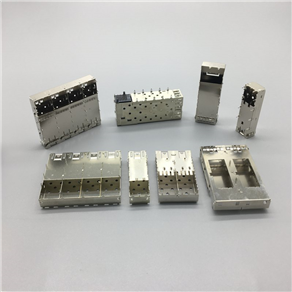

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子