Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

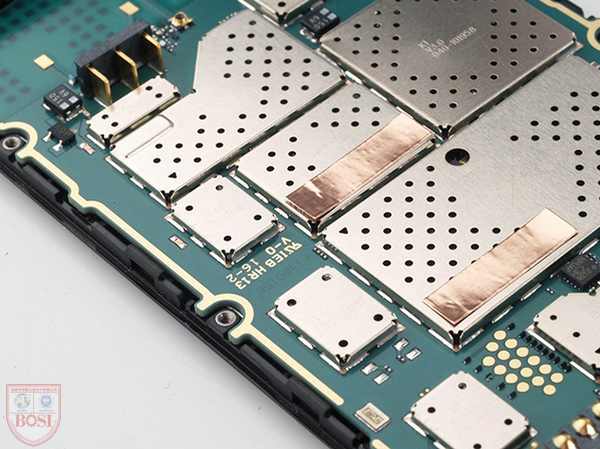

Dongguan's hardware industry is relatively developed, and there are many manufacturers of shielding covers. However, when many manufacturers produce shielding covers, the scrap rate is often too high. In this case, profits may be compressed, and orders may also be placed. If you can't finish it, you will lose money. Therefore, it is more important to solve the problem of the high rejection rate of the shielding cover. We must first understand which step caused the problem, and then prescribe the right medicine. The following will be analyzed by BOSI.

Reasons and solutions for the high rejection rate of shielding covers:

1. The quality of raw materials is not good enough.

Raw materials are the first guarantee for processing qualified stamping parts. If the hardness and surface of the raw materials do not meet the quality requirements, the corresponding stamping parts rejection rate will definitely be too high. Especially for some shields with relatively large deformation, if the raw materials are not qualified, cracking and damage will occur. Therefore, when purchasing raw materials, you must not be greedy for cheap, and you must find a reliable and regular material supplier.

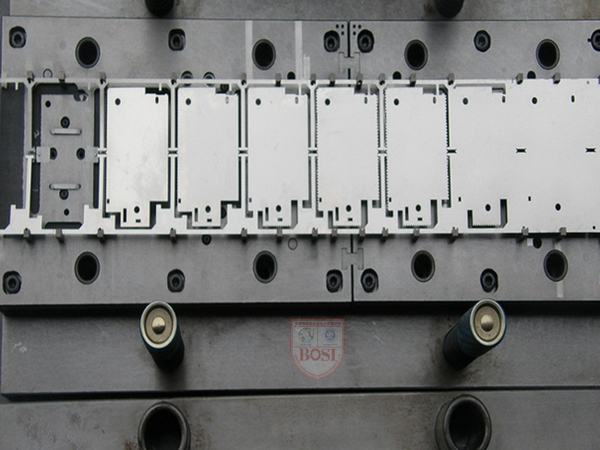

2. the stamping die installation is unqualified.

The installation of the stamping die does not meet the specifications, resulting in the failure of the upper die and the lower die to cooperate well during the stamping process, resulting in a high rejection rate. The stamping die is the foundation of processing the stamping parts of the shield cover. On the premise that there is no problem with the die, the installation is very important. Don't think that installing the stamping die is very simple, even a small error may cause the stamping parts produced to be scrap. When installing a stamping die, the concentricity, clearance, flatness, etc. of the upper and lower dies play a crucial role.

3. The mold is worn.

In the long-term use of the stamping die, wear or loose parts occur, which will also lead to product scrap. There are many stamping factories that do not carry out daily inspection and maintenance of the mold after installing the mold for production. Only when the burr is relatively large, the mold is removed and the knife edge is simply repaired. As everyone knows, the wear of the mold is not only the wear of the blade, but also some mold parts will also wear with use. After these parts are worn, it will affect the accuracy of the entire mold.

4. The workers are not standardized.

When the worker was operating the punch, he did not follow the installation manual, or there was an error in feeding.

5. The positioning device is inaccurate.

During the feeding process, the inaccurate mold positioning device will cause problems with the coordination of each process, and will also lead to waste products.

The above is the reason for the high rejection rate of shields: http://www.bosiwj.com/in-10.html

The stamping dies required for each shielding cover are different, so the specific reasons need to be analyzed in detail. If the rejection rate of the shielding cover produced is too high, you can start from these reasons first, I hope it can help you

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

How to correctly mount the manual soldering points of shielding components

How to select materials for automotive precision stamping parts?

Shenzhen shielding cover manufacturers: several reasons that affect the quality of shielding cover products

Dongguan metal stamping die manufacturers: several skills that metal stamping die processing personnel need to master

Which company is more professional in producing mobile phone shield cover in Dongguan?

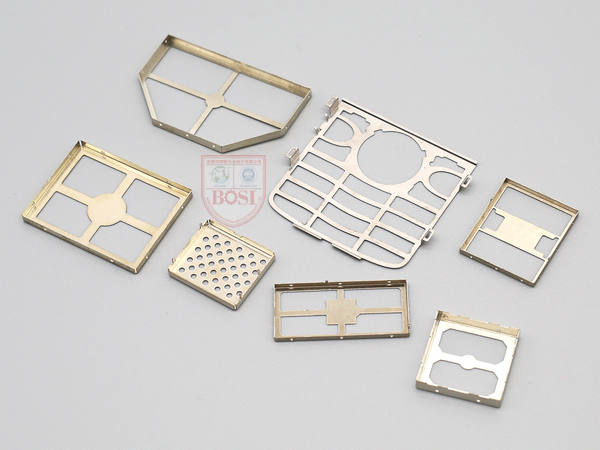

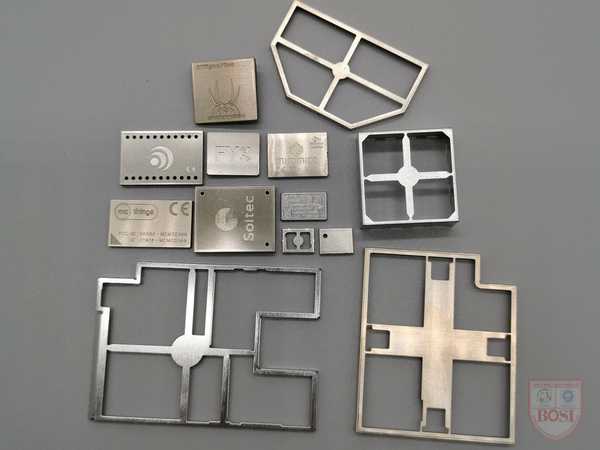

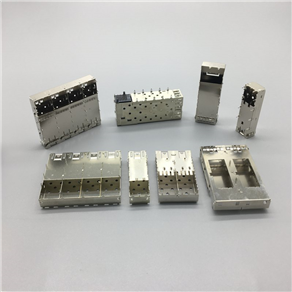

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

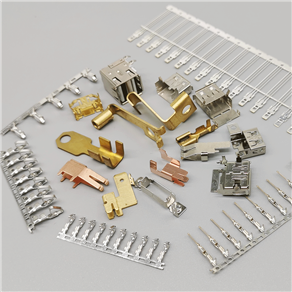

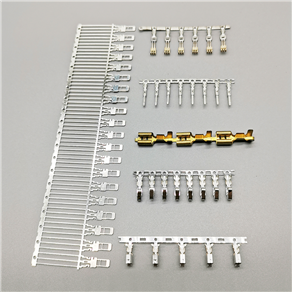

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

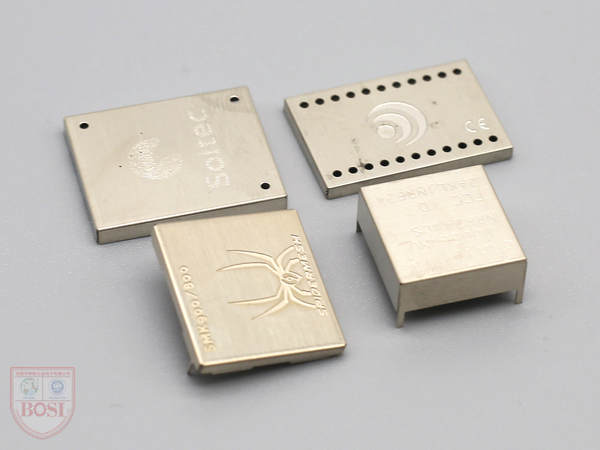

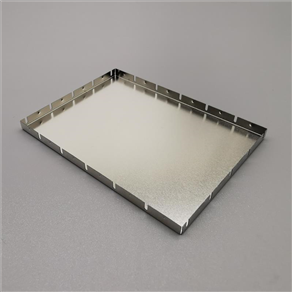

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子