Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

Nowadays, the use of metal stamping and drawing parts is more and more widely used, not only in industry, but also in life, because its drawing process can produce various shapes, such as cylinder, rectangle, ladder shape, spherical, and even other irregularly shaped thin-walled parts. So do you know what are the process types of stamping parts? The following editor will give you a look.

Types of metal stamping and drawing forming processes:

1. Stretching: Using a platen device and the punching force of a punch, part or all of the flat plate is pulled into the cavity of the concave mold to form a container with a bottom. The processing of the side wall of the container parallel to the drawing direction is a simple drawing processing, and the drawing processing of conical (or pyramidal) containers, hemispherical containers and parabolic containers, etc., also includes expansion processing.

2. Re-stretching: that is, for deep-drawn products that cannot be completed by one-time stretching, the stretched formed products need to be stretched again to increase the depth of the forming container.

3. Reverse drawing processing: reverse drawing of the stretched parts in the previous process, the inner side of the workpiece becomes the outer side, and the outer diameter becomes smaller.

4. Thinning and drawing processing: use a punch to squeeze the formed container into a concave mold cavity slightly smaller than the outer diameter of the container, so that the outer diameter of the container with the bottom becomes smaller, and the wall thickness becomes thinner, which not only eliminates the wall thickness deviation , and make the surface of the container smooth.

Matters needing attention when processing metal stamping and drawing parts:

1. The shape of metal stamping and drawing should be as simple and symmetrical as possible, and it should be formed by deep drawing as much as possible;

2. For parts that need to be stretched multiple times, under the premise of ensuring the necessary surface quality, there should be traces that can occur during the stretching process on the inner and outer surfaces;

3. Under the premise of ensuring the installation requirements, the side walls of the tensile parts must have a certain slope;

4. The interval between the bottom of the drawing piece or the hole edge on the flange and the side wall should be appropriate;

5. The corner radius of the bottom and the wall, the flange and the wall, and the four corners of the rectangular piece should be appropriate;

6. The scale marking of metal stamping and drawing parts cannot be marked with the internal and external dimensions.

The above is the editor's introduction to the processing types of metal stamping and drawing parts and the points to pay attention to when processing metal drawing parts. We Dongguan Bosi Hardware specializes in processing and producing metal stamping and drawing parts. Welcome to consult and quote.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

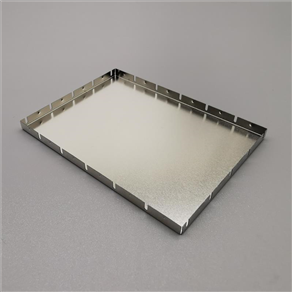

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

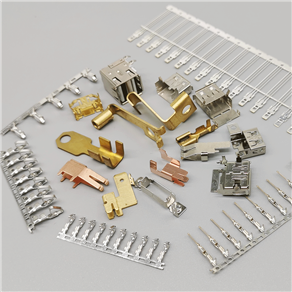

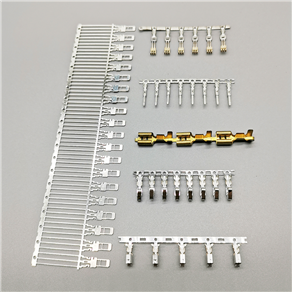

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

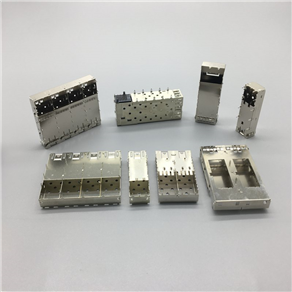

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子